Mechanical

Get in Touch

CAD For Fun

A few of my CAD models that I made for fun.

CAD Models

- Robotic Gripper

- Screw Driver

- Citrus Juicer

- Woven Basket

- Geodesic Ball

- Fidget Spinner

- Bottle Cap

Software Used:

- SolidWorks

- PhotoView 360

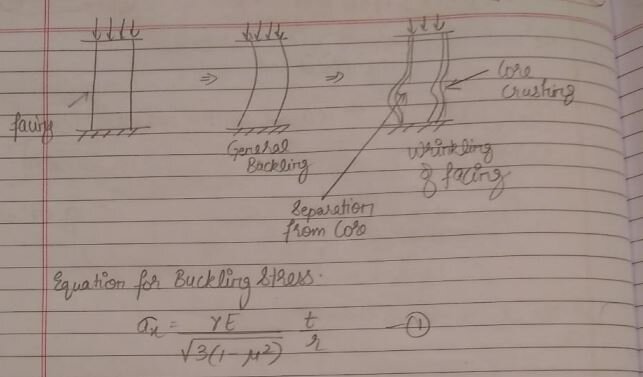

Failure Analysis Of Failed Object

Project involved failure analysis on a mechanical part that has failed (bent, broken, buckled, torn, etc.) and to write a concise report explaining why the part failed.

Findings:

- Axial compression was studied by moving down the upper plate (hand) while the lower plate was stationary.

- Gamma value was found using the correlation factors for isotropic cylinders subjected to axial compression.

- Added common causes of error to cause buckling were found to be surface roughness, inclusions, transverse surface tears, initial off-flatness of sheet, presence of hard particles to circumferential direction of the can.

- Found that in order to reduce buckling we need to increase the thickness of the walls, or use a material with high “E” value.

- Concluded that even though the buckling of the aluminum can is a result of multiple things like the amount of force, height of impact etc. but the thickness variation of the sidewall of the can is major cause of the buckling of the can, as it impacts the amount of force required to cause buckling directly.

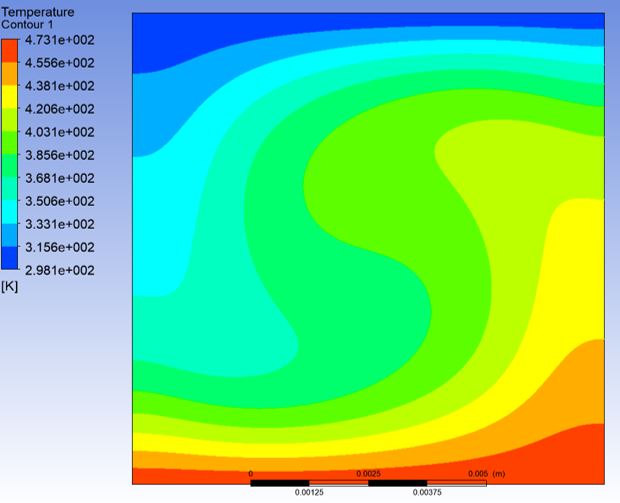

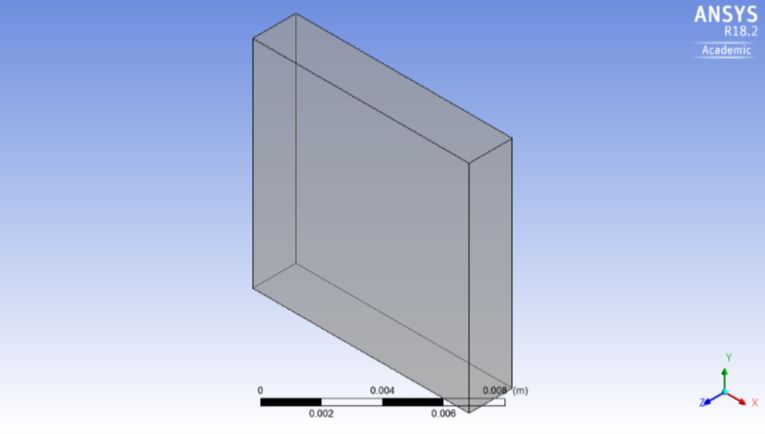

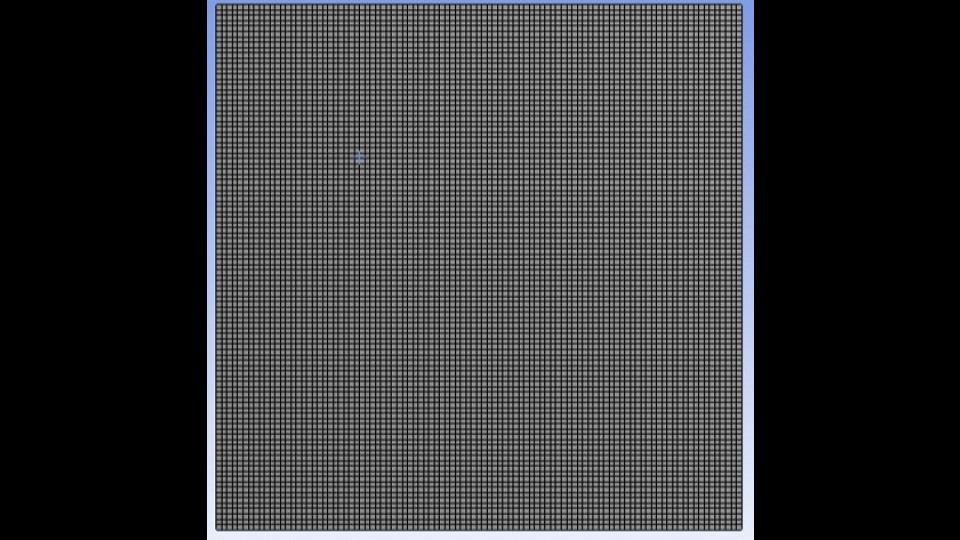

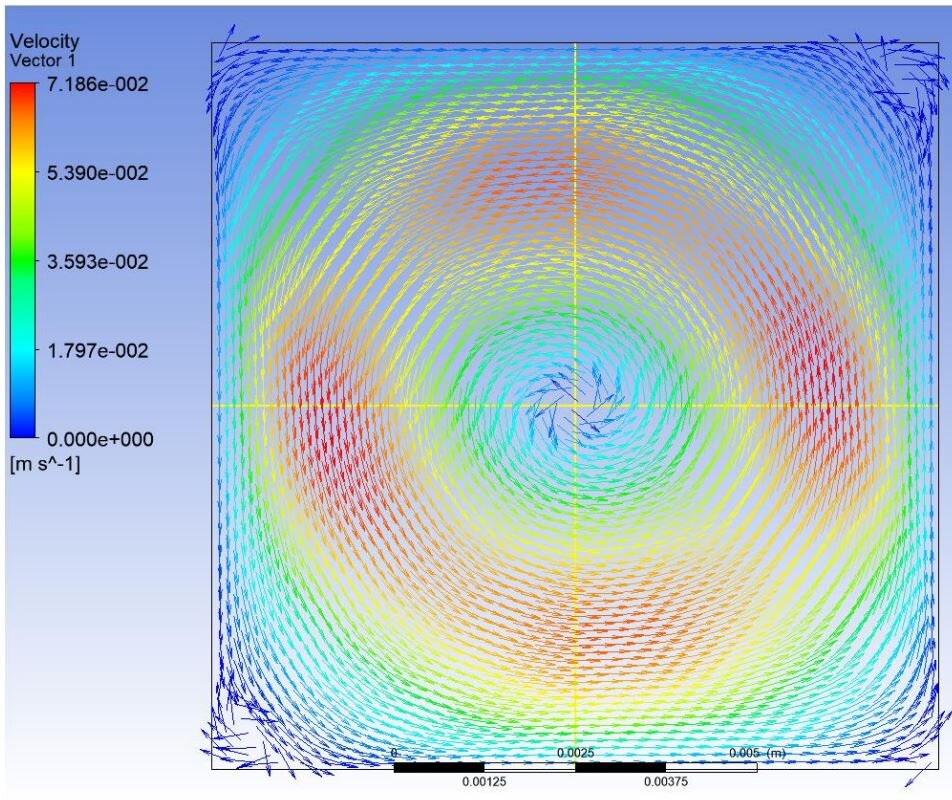

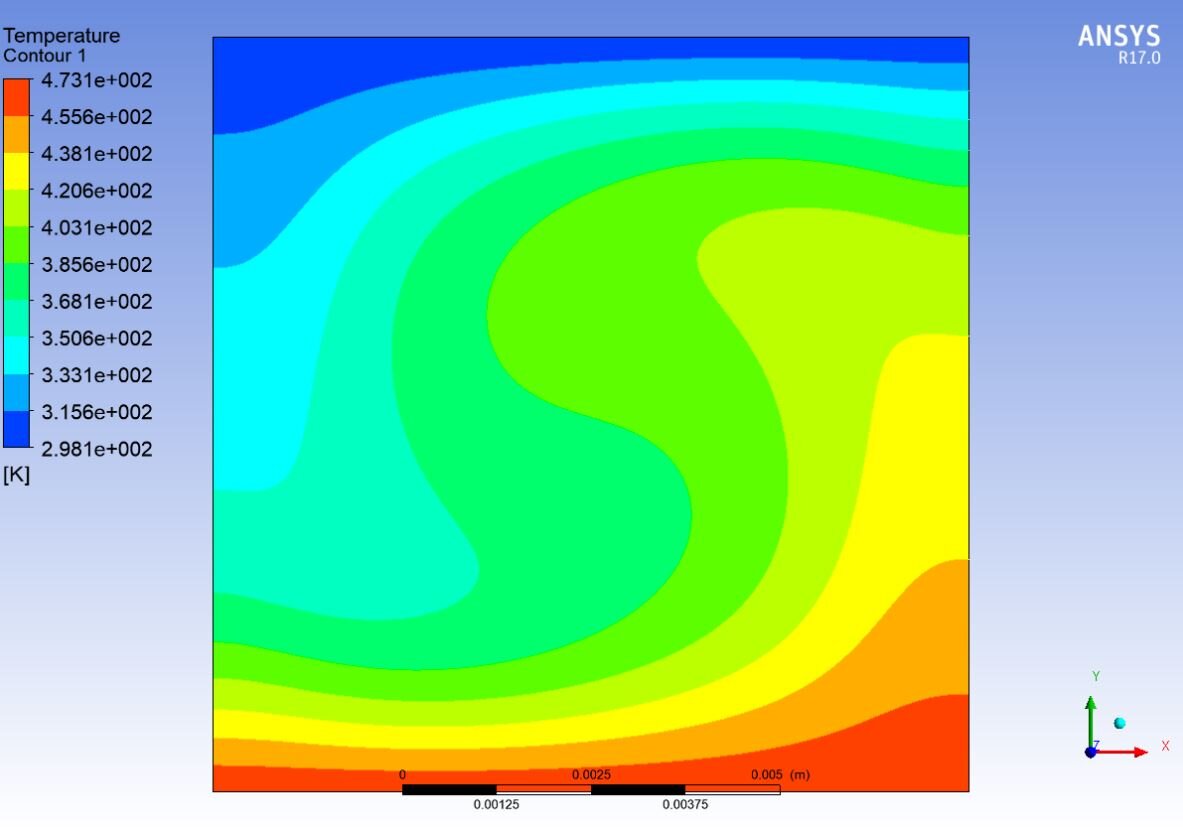

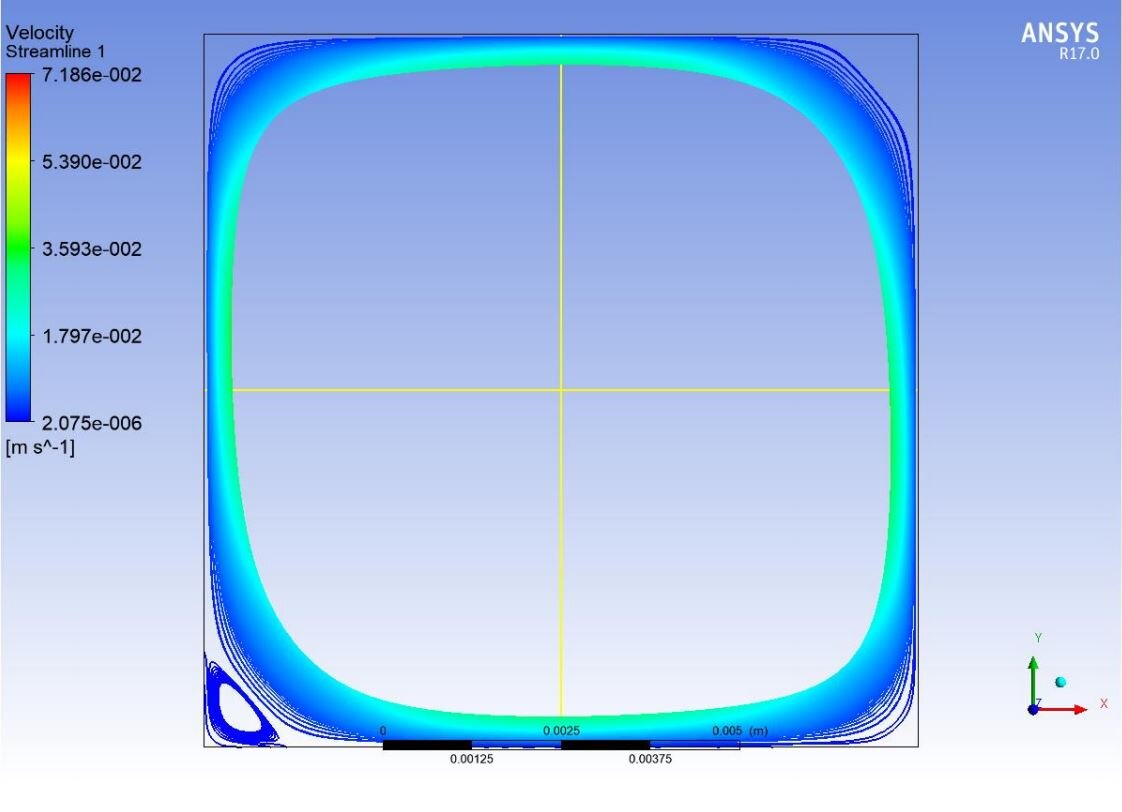

Natural Convection in Enclosure-CFD

The project was to study natural convection in an enclosure with four walls of the enclosure having different thermal boundary conditions to create different flow structures.

Role

- Investigated flow streamlines and temperature distributions inside the enclosure for the three different conditions.

- Plotted the velocity vectors, contours, centerline velocity profiles of each condition.

Software Used

- ANSYS

- Siemens NX

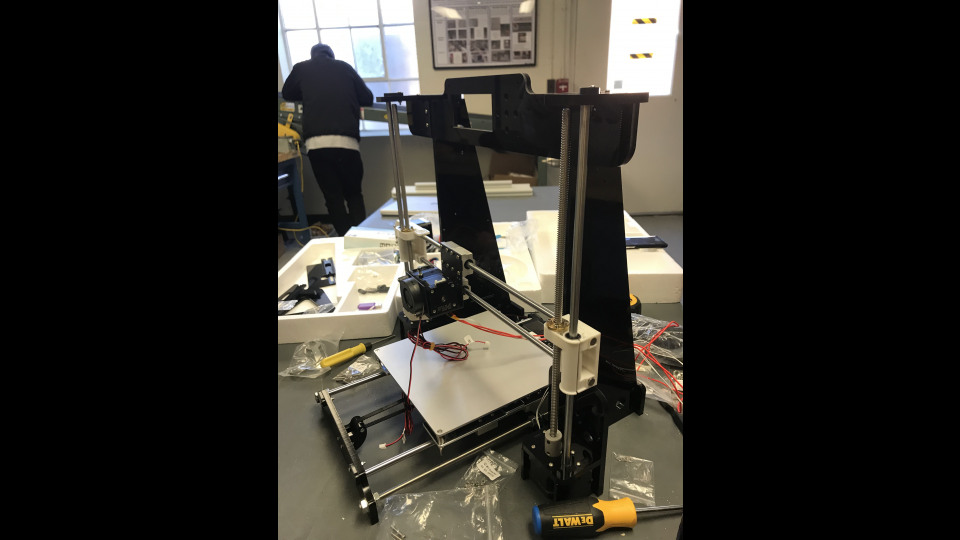

3D Printer Assembly-Wiring

The project was to complete the assembly of a FDM printer from scratch, take pictures and clearly annotate your printer with the following items:

- Subsystems: Filament feeder system, Print head, Heater/Heat sink, Gantry, Build Plate.

- Functional mechanical subsystems, electrical systems, controller, motors, power supplies, linear actuators, feedstock materials, types of all data cables.

- Functionality modules: Feed Raw Material, Liquefaction, Extrusion, Solidification.

- Helped in assembly and wiring of the 3D Printer.

- Annotated Functionality modules and Subsystems like Heater/Heat sink, Gantry and Build plate.

Role

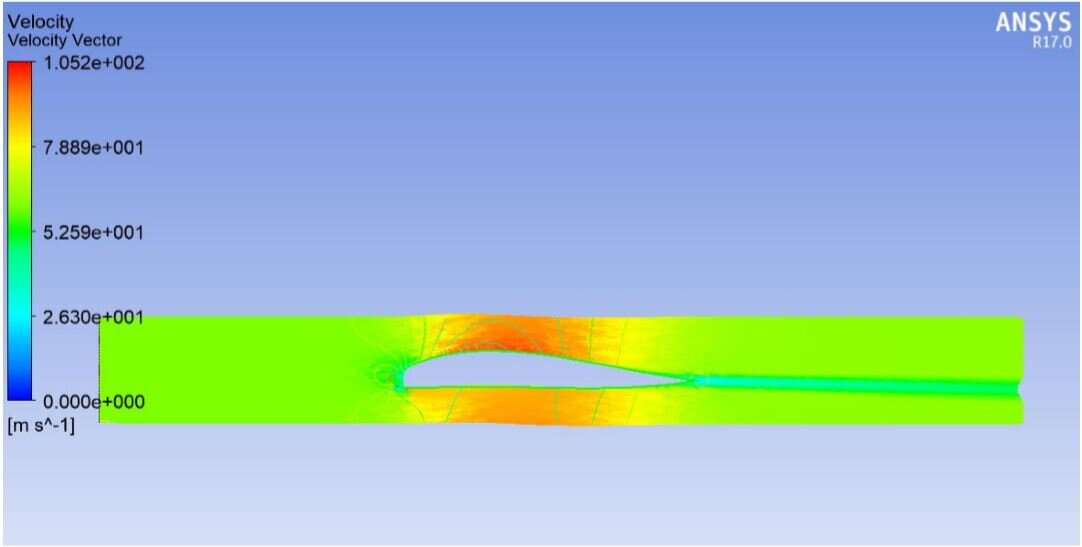

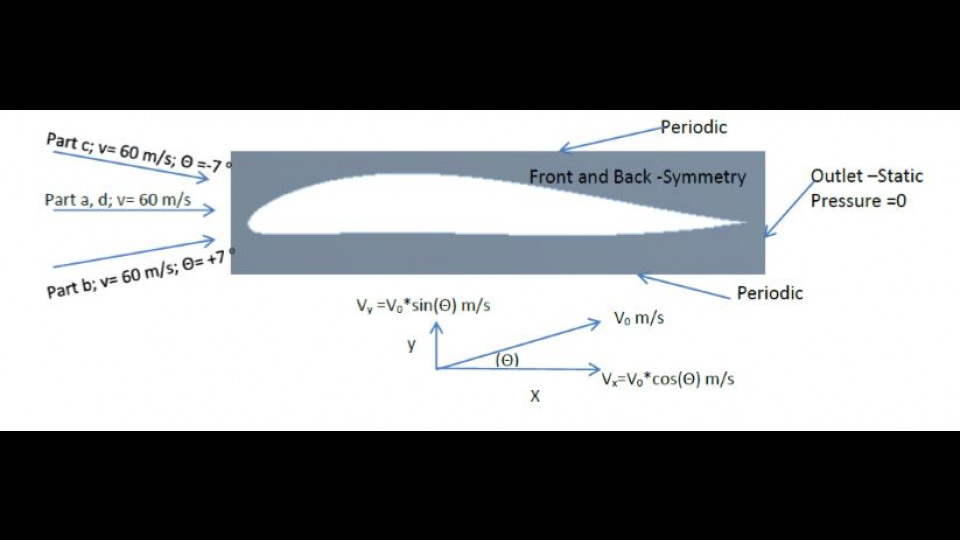

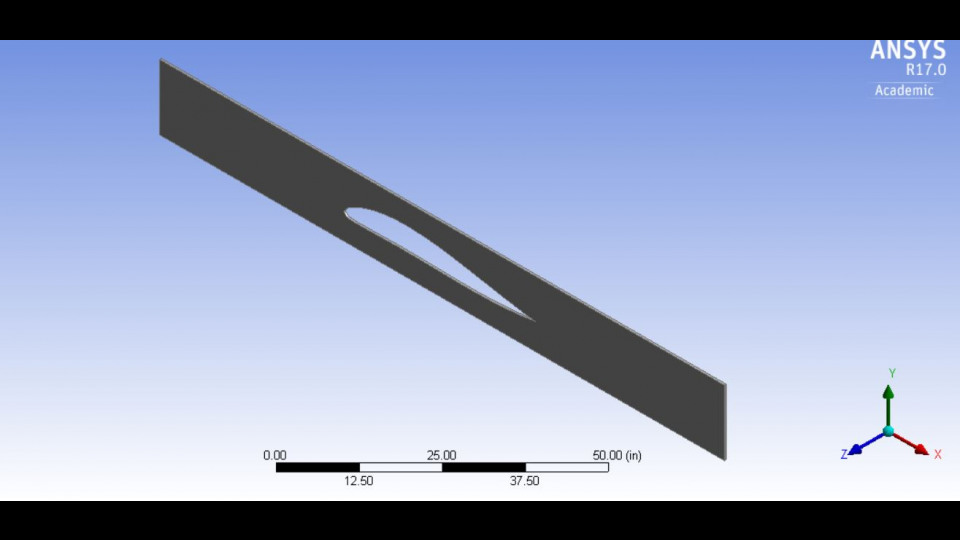

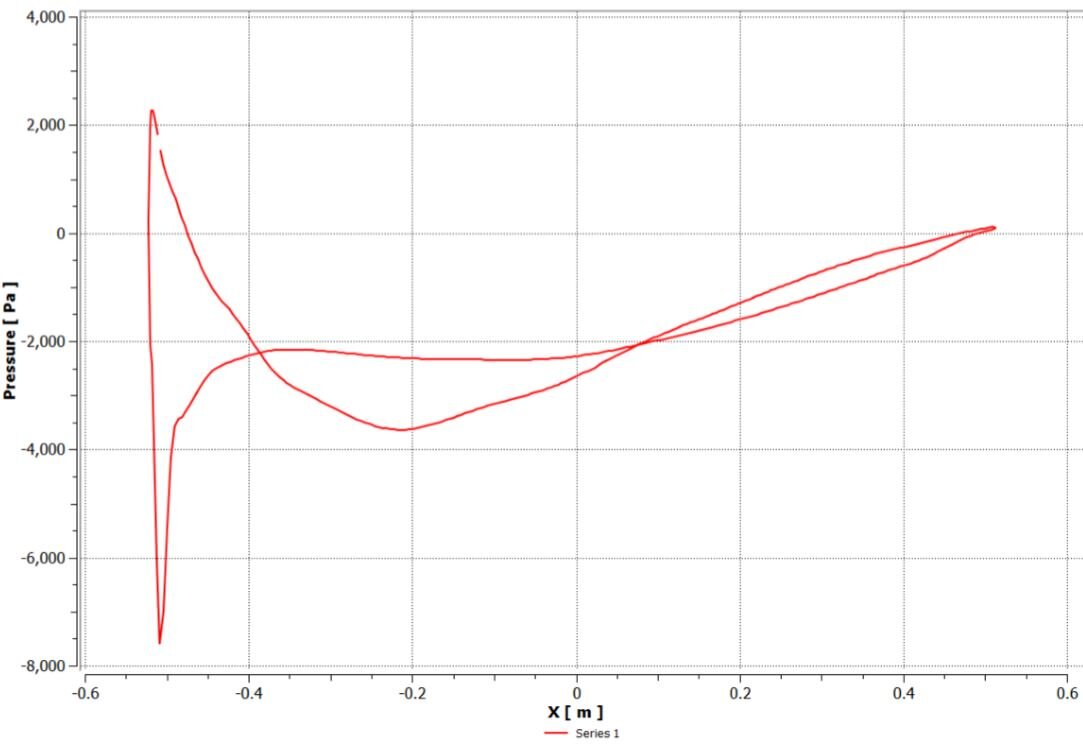

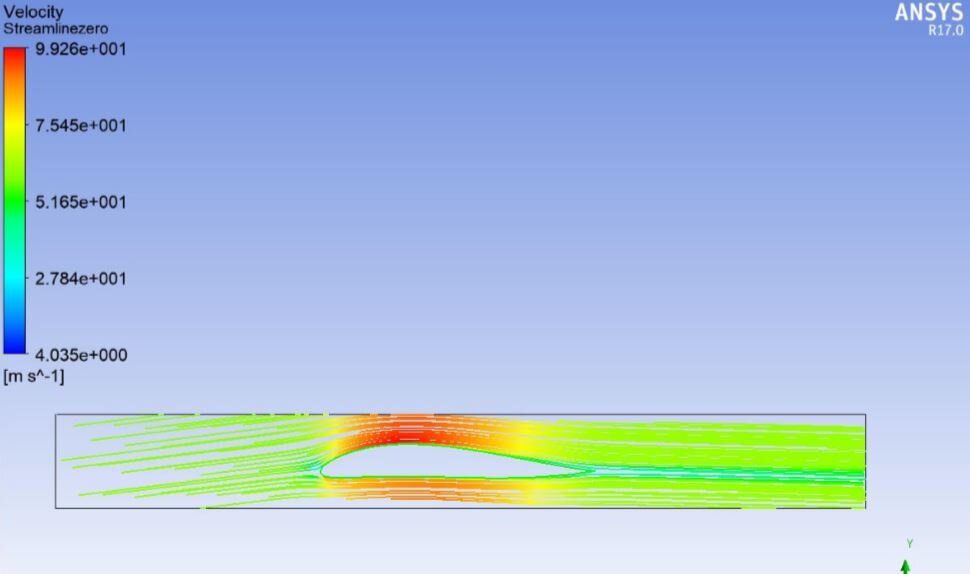

NACA M18 Airfoil

The project was to analyze the flow over a NACA M18 airfoil at various incidence angles.

Role

- Plotted the velocity vectors, contours, centerline velocity profiles of each condition.

- Improving the quality of its motion while following the line like reducing the jerking behavior.

- Lift/Drag analysis of the aluminium airfoil at each incidence angle.

Software Used

- ANSYS

- Siemens NX